Introduction

The metal fabrication industry has evolved significantly over the past decade, with manufacturers increasingly relying on technology to achieve precision, efficiency, and consistency. Among the most impactful innovations is the 6 axis press brake, a machine that provides operators with six independent points of control to perform complex bending operations. By leveraging these capabilities, fabrication shops can achieve precise angles, reduce errors, and complete multi-step operations in a single setup. Industries ranging from automotive and aerospace to construction and heavy machinery benefit greatly from the accuracy and versatility offered by these machines. Understanding the role of each press brake axis and optimizing its use is key to maximizing efficiency and product quality.

Overview of the 6 Axis Press Brake

What Makes it Different

Traditional press brakes often have limited axis control, making multi-step bends time-consuming and prone to error. In contrast, the 6 axis press brake allows for simultaneous control of six axes, including the ram, back gauge, front and rear positioning, and tilt or side adjustments. This multi-axis control enables operators to perform complex bends without repositioning the workpiece manually, reducing setup times and increasing accuracy.

Key Components

A proper understanding of the machine’s components ensures optimal operation:

- Ram or Punch: The moving component that presses the sheet into the die to form a bend.

- Die: The stationary tool that shapes the material.

- Back Gauge: Precisely positions the workpiece along one or more axes.

- Control Panel: Programs bend sequences, angles, and material-specific parameters.

- Safety Systems: Guards, light curtains, and emergency stops protect operators during operation.

Mastering these components allows operators to fully utilize the press brake axis functionality while maintaining a safe working environment.

The Role of Each Press Brake Axis

Ram Axis

The ram axis controls the vertical movement of the punch, determining the depth and angle of each bend. Proper use of this axis ensures uniformity across multiple workpieces, minimizes material waste, and guarantees consistent results.

Back Gauge Axes

Back gauge axes, typically referred to as X and R axes, are critical for positioning the sheet accurately. Correct alignment along these axes ensures repeatable bends and helps maintain tight tolerances across production runs.

Front and Rear Axes

The front and rear axes allow precise adjustments along the length and width of the sheet. By using these axes, operators can execute compound bends and work with irregularly shaped components without manually repositioning the workpiece, improving efficiency and precision.

Tilt and Side Axes

Tilt and side axes control the angular and rotational positioning of the sheet. These axes provide versatility in performing complex bends, enabling operators to handle intricate designs with minimal manual adjustments and improved accuracy.

Advantages of a 6 Axis Press Brake

Exceptional Accuracy

The ability to control multiple press brake axis points simultaneously ensures highly precise bends. High accuracy is essential for industries such as aerospace and automotive, where even minor deviations can affect performance and safety.

Improved Productivity

With multi-axis control, setup times are reduced and manual adjustments minimized. Operators can program complex bend sequences for repeat production, reducing errors and increasing throughput.

Versatility

The 6 axis press brake can accommodate a wide range of materials, thicknesses, and bending operations. Its multi-axis capability allows completion of multi-step bends in a single setup, reducing the need for multiple machines or frequent tooling changes.

Reduced Material Waste

Accurate bends and repeatable operations minimize scrap. Proper use of each press brake axis ensures that components meet specifications on the first attempt, lowering production costs and supporting sustainable manufacturing practices.

Preparing for Operation

Safety Measures

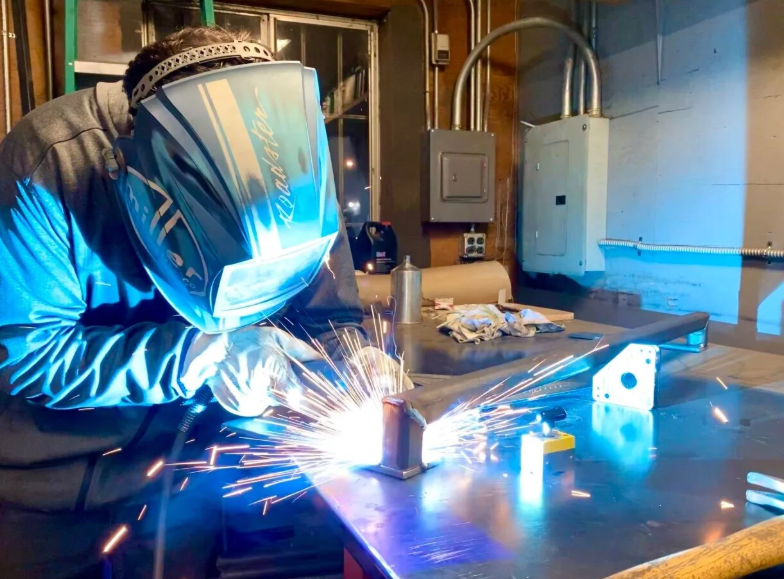

Operating a 6 axis press brake requires strict adherence to safety protocols:

- Wear personal protective equipment, including gloves, safety glasses, and steel-toed shoes.

- Ensure guards, light curtains, and emergency stop mechanisms are functional.

- Follow manufacturer and company-specific safety guidelines at all times.

Emphasizing safety protects operators and maintains a productive work environment.

Material and Tooling Setup

Proper setup ensures quality results:

- Select punches and dies suitable for the material and thickness.

- Secure the sheet metal to prevent movement during bending.

- Verify that all press brake axis settings align with the workpiece specifications.

Accurate setup reduces errors, material waste, and production delays.

Machine Calibration

Calibration of each axis is essential for precision:

- Adjust the ram, back gauge, and additional axes according to desired bend angles and dimensions.

- Confirm that programmed sequences match production requirements.

Proper calibration guarantees consistent and repeatable results across multiple workpieces.

See also: Why Vibration Monitoring Is Important for Predictive Maintenance

Operating the 6 Axis Press Brake

Programming the Machine

Correct programming is vital for reliable production:

- Input material type, thickness, and sheet dimensions.

- Define bend angles, radii, and sequences.

- Save programs for repeated use to improve efficiency and reduce errors.

Effective programming minimizes mistakes and optimizes workflow.

Loading and Positioning

Proper placement of the sheet is critical:

- Align the sheet with the back gauge and ensure it rests flat against the die.

- Secure the sheet to prevent shifting during bending.

Accurate positioning ensures precise bends while protecting both operator and material.

Performing the Bend

During operation:

- Monitor alignment and movement throughout the process.

- Keep hands and body clear of moving components.

- For complex bends, perform incremental adjustments to maintain control and accuracy.

Careful operation ensures each bend meets specifications safely.

Inspection and Adjustment

After bending:

- Remove the workpiece carefully.

- Inspect angles, dimensions, and overall quality.

- Adjust press brake axis settings or programming if necessary for subsequent operations.

Regular inspection maintains consistent quality and prevents errors in production.

Maintenance and Troubleshooting

Routine Maintenance

Routine maintenance keeps the machine performing optimally:

- Lubricate moving components to reduce wear.

- Inspect punches and dies for damage or wear.

- Check hydraulic and electrical systems regularly.

- Test safety systems frequently.

Preventive maintenance reduces downtime and prolongs machine life.

Troubleshooting

Common issues include:

- Misaligned Bends: Adjust the press brake axis or reposition the workpiece.

- Inconsistent Angles: Inspect tooling, recalibrate axes, and verify material specifications.

- Machine Malfunctions: Review programming, check hydraulic and electrical systems, and follow troubleshooting procedures.

Prompt problem-solving ensures smooth and accurate production.

Training and Best Practices

Operator Training

Training maximizes machine efficiency and safety:

- Understand all press brake axis functions and components.

- Learn safety protocols and emergency procedures.

- Gain hands-on experience with programming, operation, and troubleshooting.

- Develop skills in routine maintenance.

Well-trained operators ensure safe, efficient, and high-quality production.

Cultivating a Safety Culture

A strong safety culture reduces accidents and improves productivity:

- Encourage reporting of hazards and unsafe practices.

- Enforce standard operating procedures consistently.

- Conduct regular safety meetings and refresher courses.

Prioritizing safety ensures adherence to best practices and protects both operators and equipment.

Documentation

Maintaining records of programming, maintenance, and inspections supports repeatable quality, regulatory compliance, and continuous improvement.

Conclusion

The 6 axis press brake has redefined metal fabrication by providing unmatched precision, efficiency, and versatility. Mastery of each press brake axis allows operators to perform complex bends with minimal error, making these machines essential for modern manufacturing. Proper setup, accurate programming, strict adherence to safety protocols, and routine maintenance are all critical for achieving consistent, high-quality results. By effectively using a 6 axis press brake, manufacturers can optimize workflow, reduce material waste, and meet the stringent standards of industries such as aerospace, automotive, and construction.